As you could probably tell by now, I’ve fallen back down the familiar rabbit hole of diesel-powered motorcycles. There aren’t many of them out there, at least compared to all of the gasoline-powered and electric motorcycles that you can find throughout history. The handful of diesel motorcycles that do exist get pretty wild. Sure, you’re not going to find a diesel Hayabusa, though that would be epic, but you will find motorcycles made to just sip on morsels of fuel like the Royal Enfield Diesel from Monday, bikes with diesel car engines, or one meant to help solve the needs of North Atlantic Treaty Organization (NATO) nations. That’s what you’re getting with today’s HDT M1030M1. And it’s actually pretty awesome. The HDT M1030M1 was birthed out of an effort to streamline fueling in the military. As the Modern War Institute at West Point explains, keeping a wide variety of equipment on the field running required some interesting logistics: As the Modern War Institute and SAE International write, in the late 1980s NATO nations began an effort to streamline the fueling process. Instead of carrying various fuels for different vehicles, the militaries worked towards “one military fuel for all the land-based military aircraft, vehicles and equipment employed on the military arena.” It’s known as the Single Fuel Concept (SFC) and the fuel selected for the task is JP-8 fuel, which is similar to commercial aviation Jet A-1, but contains a corrosion inhibitor, a lubrication additive, and an anti-icing additive. The advantage of JP-8 is that it could be used to fuel a jet and also be used to fuel a truck. Our Jason Torchinsky further notes that this stuff is similar to the fuel used to heat some homes. Or, in this case, JP-8 also fuels a motorcycle. The HDT M1030M1 is the work of Hesperia, California-based Hayes Diversified Technologies and the UK’s Cranfield University. Founded in 1961, Hayes had previously worked on other military motorcycles like the M1030, a 1980s and 1990s Kawasaki KR250 adapted for military use. The company also built the M1030B1, a gas-engine Kawasaki KLR650 adapted for military use. Hayes, along with Cranfield University, would take the M1030B1 and develop it into a motorcycle that fit the Single Fuel Concept. In November 2004, the EurekAlert! science journal reported that the first diesel-powered KLRs hit the road. It was hailed as the world’s first production diesel military motorbike, and the first motorcycle of any kind to have a diesel engine built for the purpose. Hayes and Cranfield University had a tall order with this motorcycle. The M1030M1 had to be sufficiently lightweight and powerful enough for tactical use, all while being reliable. And of course, it had to be able to run on diesel or JP-8. Engineers from the university John Crocker and Dr. Stuart McGuigan worked with HDT for what sounds like one ridiculously cool machine, from EurekAlert!:

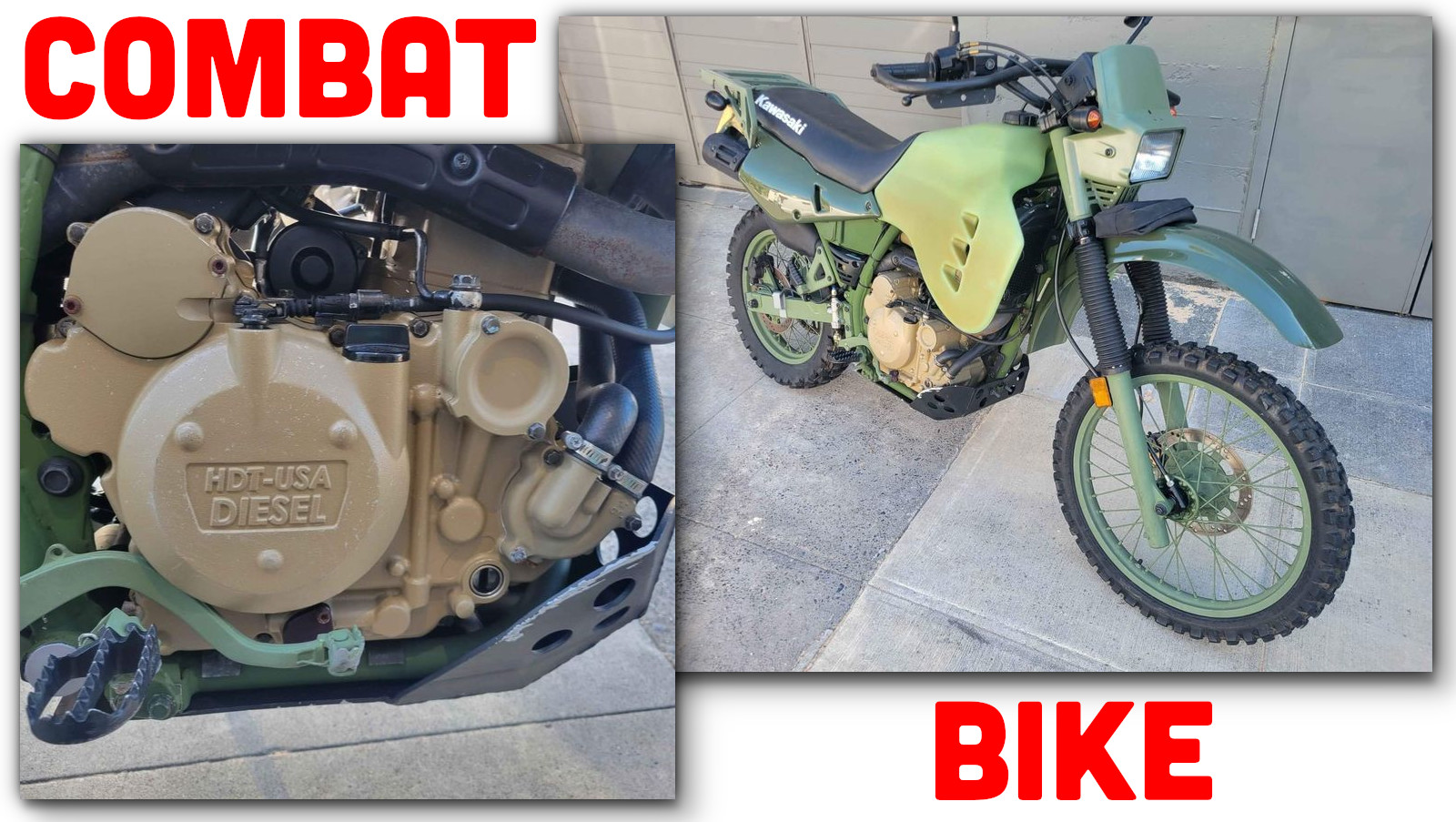

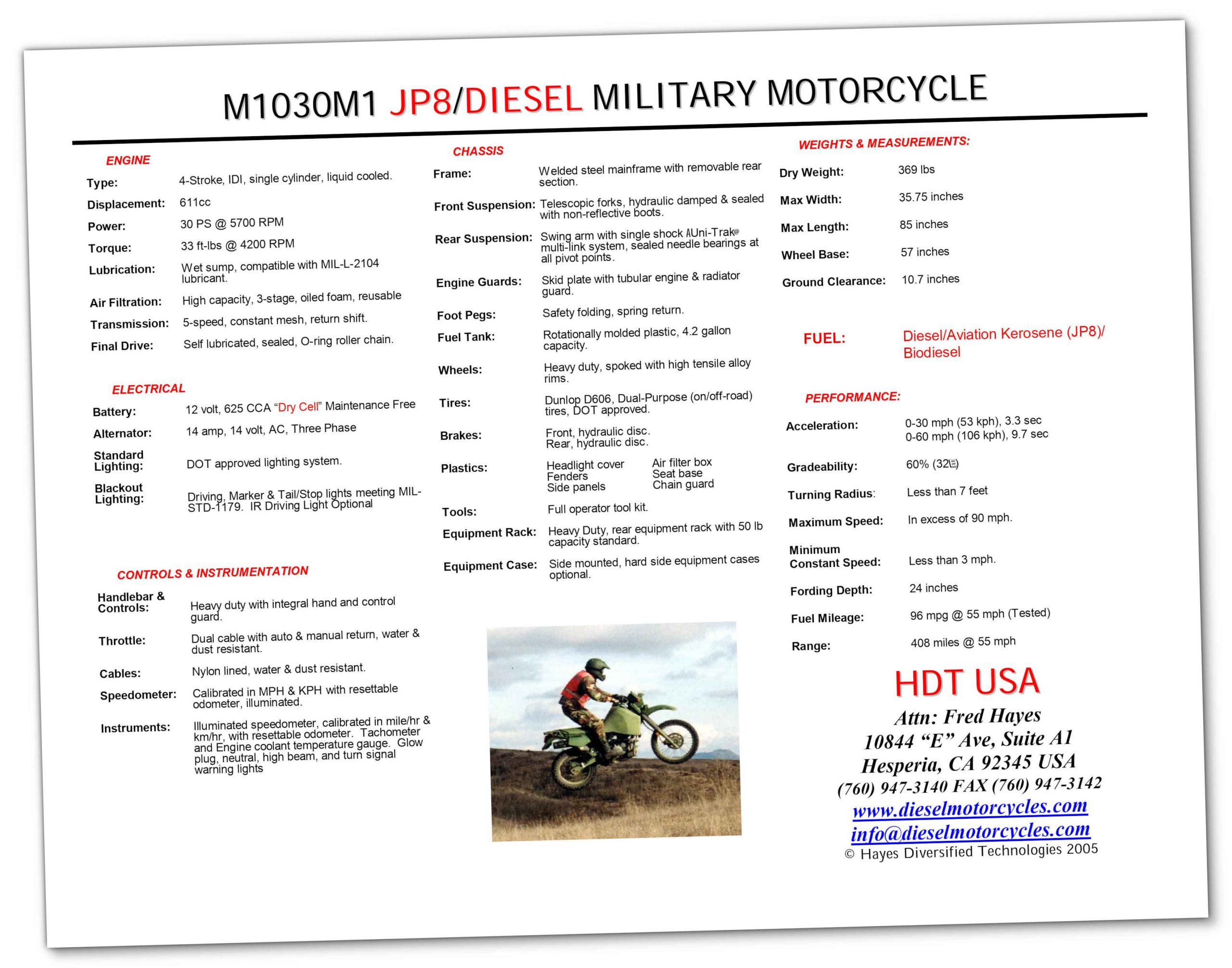

Fred Hayes, founder of HDT, who was in the saddle at the world famous Bonneville Salt Flats, Utah, said: “The event was marred by rain the previous week and by poor track conditions, which limited the top speeds due to soft, wet salt. The normally aspirated bike was officially timed by the AMA at 85.466mph, against our calculated top speed of 86mph with production gearing. The calculated speed was at sea level (4350ft) on hard pavement. We’re delighted with the result. If we’d had an option for gearing and more track time, we may have broken the 90mph barrier.” By the publication of that article, the U.S. Marines placed an order for 522 of the machines with the U.S. Army and a number of NATO nations expressed their own interest. Hayes had beaten an array of other companies for the contract, which even included a team consisting of Harley-Davidson and Lockheed. The M1030M1 is powered by a 611cc single-cylinder indirect injection diesel making 30 horses and 33 lb-ft torque. That’s down from the 42 horses and a touch under the 34 lb-ft torque of a normal KLR650. HDT advertised that the motorcycle was capable of achieving 96 mpg at 55 mph. The motorcycle also has 60 percent gradeability, an equipment rack that can hold 50 pounds, a water fording depth of two feet, and a 4.2-gallon fuel tank. For those of you counting, that means a range of around 403 miles on a fill. Perhaps my favorite part is that this motorcycle goes against what’s commonly reported about diesel motorcycles. If you search for the downsides of diesel motorcycles, you’ll often find claims that diesel engines are too heavy for practical use in a motorcycle. While this may arguably be true for something like that Royal Enfield Diesel, the HDT M1030M1 was advertised as having a 369-pound dry weight, or just 32 pounds more than the 337-pound dry weight of the donor KLR650. Reports at the time noted that Hayes was working on a civilian version. However, when Cycle World asked Hayes about it, the company’s founder noted that demand from different militaries was so high that the small outfit didn’t have the workforce or the production line for a civilian version. The military bike did get a sequel with the M1030M2, which bumped displacement up to 670cc and power to 33 HP. That one reportedly went 121.2 mph at Bonneville. While the military ordered 522 of these, some reports suggest that just 440 of them were actually delivered. It’s also unclear how many of the M1030M2 exist. Over the past handful of years, these motorcycles have been coming out of duty and onto government surplus auctions, where they get scooped up by civilians. When I first discovered these motorcycles back in 2018, I saw auctions selling for around $5,000. Today, I’m now seeing them sell for $9,000, $10,000, or even nearly $15,000 at government auctions. A few readers also tried selling me theirs for $15,000. I couldn’t find any currently up for auction right now, but I did find three for sale in private hands. There’s one on eBay that won’t start for $12,500 and two on Facebook for $14,995 and $20,000, respectively. With prices like these, I fear I missed the boat on a cheap diesel motorcycle. That’s a shame because these look like a ton of fun. Support our mission of championing car culture by becoming an Official Autopian Member. Harley-Davidson Might Be Importing A Small Motorcycle Into America From China One Of The Only Mass-Produced Diesel Motorcycles In The World Allegedly Gets 200 MPG And Is For Sale In America Powering A BMW Motorcycle With An Air-Cooled Volkswagen Engine Is A Thing And It’s Amazing The Yamaha Moko Powa D10 Is A Futuristic Motorcycle From A Company That Disappeared Without A Trace The KLR650 is a great bike though, just feed it 87 octane 10% corn squeezing gas and it is happy. (-: So for a geezer that wants a motorcycle that’s as reliable as a hammer and hasn’t ridden in 50 some years ( my last bike was a 57 BSA gold star 500cc hill climb bike , manual spark advance so the kickstart snapped off and I had to push start it ) are the regular KLR650s a good choice? 2007 and older (1st gens) are more off-road focused and a bit lighter. 2008 and up (2nd gens) are more of an ADV style bike and are great all-rounders. 2022+ (3rd gens) are like upgraded 2nd gens with fuel injection. The biggest perk to the KLR is that they’re CHEAP but reliable. You may end up deciding to swap sprockets or do suspension mods to really hone the bike to your style, but none of that is necessary to enjoy it and even if you did put that money down, it’d still be cheaper than a Tenere 700 or a Africa Twin. Also, I’ve seen several people in my groups hit over 150,000 miles on their KLRs, so there’s that. Here’s a recent test: https://www.youtube.com/watch?v=3CEJmeTrAXM And an opinion piece: https://www.youtube.com/watch?v=W7upTCN3M4s https://youtu.be/rvGZS5fqxrk Still, fun to hunt. https://hips.hearstapps.com/amv-prod-gp.s3.amazonaws.com/gearpatrol/wp-content/uploads/2016/05/Kawasaki-KLR-Gear-Patrol.jpg A Marine on the flight deck of an amphibious assault ship, with a CH-53E Super Stallion heavy-lift helicopter in the background. This helo is being replaced by the even-huger CH-53K King Stallion. https://s3files.core77.com/blog/images/2012/09/id_klr_250d8_700.jpg https://upload.wikimedia.org/wikipedia/commons/thumb/3/34/US_Navy_050418-N-3557N-071_Marines_assigned_to_the_26th_Marine_Expeditionary_Unit_%28MEU%29_transit_the_flight_deck_to_load_KLR_250-D8_Marine_Corps_motorcycles.jpg/1200px-US_Navy_050418-N-3557N-071_Marines_assigned_to_the_26th_Marine_Expeditionary_Unit_%28MEU%29_transit_the_flight_deck_to_load_KLR_250-D8_Marine_Corps_motorcycles.jpg Two Marines on a flight deck at sea and about to load onto CH-46 Sea Knights. Nicknamed “Phrogs,” the helicopters been replaced by the V-22 Osprey tiltrotor. The great advantage of diesel engines for the Marine Corps is that it’s a “heavy fuel:” it’s far safer aboard ship. The “naval Services,” which refers to both the U.S. Navy and the U.S. Marine Corps,* try to use JP on every vehicle possible, down to unmanned aircraft systems, in order limit the challenges of transporting, storing, and pumping much more volatile gasoline at sea. Having a common fuel ashore is also a great advantage so that, as you describe, Navy and Marine Corps forces need move and manage a single fuel from ship to shore.

- No, the U.S. Marine Corps is not part of the U.S. Navy. It isn’t. It really isn’t. https://autos.maxabout.com/bikes/hero/rnt/rnt-diesel https://www.eta.co.uk/2014/02/14/the-hero-rnt-a-diesel-motorcycle-thats-a-two-wheeled-pickup/ I would love to know if they are real! For me the fact that gas evaporates is a bonus, not a downside, but I understand how it’s very different for the Military. Truth is, the physics of diesel motorcycles is inherently compromised, even if this one was serviceable. So, using my sour grapes logic, it’s probably better I never got one. My next unicorn to imagine, is going to be a PHEV bike. Yeah, that’s the ticket! Also diesel engines can rev the fuel supports it. Most engines have such heavy duty parts the redline is from mass not flame speed. My 1.5 na diesel would scream with a 6500rpm fuel cut. With enough timing advance and a lean enough mixture to burn before the next cycle diesel can male power up to around 7000rpm. My 1.9 with an HY35 doesnt even make more than 2psi boost until it spools at 4200rpm and pulls hard to 6600. It would rev faster but you know my pistons are twice the mass of a chevy 350 piston and makes them look like little kid toys if side by side. Bigger diesels dont rev beyond 3000rpm, some redline at 2000rpm. Big ones in ships redline at 800rpm. Its mass not the fuel. In comparison, a diesel engine’s burn rate at high loads is strongly dependent on the fuel injection rate, subsequent mixing with air and vaporization, most of which are more dependent on absolute time instead of engine speed. First, a not-so-quick primer on the diesel combustion process. First, fuel is injected at very high pressures typically about 10-20 degrees before the piston reaches TDC, lasting for for 20-40 crank degrees depending on the engine. Once the fuel is injected, it has to break apart into lots of little droplets with lots of surface area for their volume, vaporize, find oxygen, and then combust. This is pretty easy for the first 20% of fuel injected – it’s getting sprayed into a chamber full of high pressure & temperature air that’s relatively stagnant, so the tip of the spray breaks apart easily, vaporizes due to the compressed gas temperature, and finds plenty of willing O2 dance partners. All this takes a bit of time, but then the first 20% or so goes up in a big spike (typically called the pre-mixed ignition spike). The next 60% of fuel is injected into the already burned column left by the first 20% which is already moving away from the injector which hurts droplet break-up, is hotter which helps vaporization, but is oxygen deficient, so even though this spray is vaporized it still needs to travel outside the burned jet left behind by the first 20% before it can find the O2 needed for combustion. When it finds the O2, it already has an ignition source from the first 20%’s pre-mixed ignition, so the combustion rate is dictated by the time it takes for break-up, vaporization, and mixing with O2 to take place. All of this takes more time (relatively anyway) than for the first 20% of the diesel jet, or for easily vaporized gasoline that was injected much earlier in the cycle in the SI engine. The last 20% is the hardest, especially if you’re at the typical high-load AFRs of about 18:20 parts air/part fuel that diesel engines run at to avoid too much soot. This last bit of fuel needs to work even harder for the droplets to break apart and find O2. By this point almost all of the O2 in the piston bowl has been consumed, so some portion of this last 20% of the fuel needs to make its way out of the bowl and up into the squish-region where conditions are cooler (very little direct combustion and higher heat losses due to the close proximity being “squished” between head and piston near TDC). Fortunately, as the piston moves downward, the gaseous contents of the piston bowl are drawn up into the volume above the piston where the remaining O2 is, but at this point its already getting towards the middle of the expansion stroke where any additional pressure that’s gained by combustion can do less work mechanically. Also, the temperature is getting colder due to the expansion, which starts to slow down any remaining reactions that are underway, freezing the intermittent species formed during combustion as CO, smaller unburned HCs, and carbon particles. As this continues, the unburned HCs preferentially agglomerate on the carbon particles, making soot that is even less likely to burn even if it finds O2 due to the colder in-cylinder temperatures. Even if it does burn, the piston’s continuing to approach BDC, so the amount of useful work it can do on the piston is minimal, so any energy just goes into heat that’ll be wasted out the exhaust (the turbine can harvest a little bit of this, but only if the wastegate is closed and the engine can handle more boost). A modern turbocharged common-rail diesel (which this bike is not!) will increase the fuel pressure at high loads more quickly than a mechanical injection pump to allow the time that the injector is open and spraying fuel to be a bit shorter, but there are diminishing returns here since you still need to deal with fluid momentum, compressibility, losses through very tiny injection holes etc. In the end, the injection event is still typically about as long gasoline combustion event (at least with OEM rail pressures and injector sizes designed to run well over the entire engine speed range). Higher injection pressures also help the droplet break-up & vaporization, and increases the spray penetration, but this only helps as long as you aren’t already spraying the bowl walls. Multiple short sprays can also help by essentially pre-mixing the first 20% of fuel, allowing a gap for fresh air to fill in, then spraying into that gap. Modern injection hardware can do this, but it’s very tricky to get right, costly, and requires a LOT of calibration once you get into 3, 4, or 5 pulses. This also elongates the entire injection event, so there are diminishing returns since the tail of combustion gets later in the cycle when the piston can do less work. High levels of air swirl (bulk rotation of the air about the cylinder’s axis, induced by the intake port design) also helps by spinning fresh air into the sides of the “flower” of injection jet plumes to increase mixing with O2; this option does introduce better high-engine-speed performance since the amount of swirl is dependent on engine speed, but often the effect is limited because generating that swirl hurts the volumetric efficiency – you need more boost to push the same amount of air in, and you need to pay for that boost with back-pressure, which increases the pumping losses, internal level of exhaust gas residual, and heat losses to the cylinder walls due to the swirl. So, in short (or TL-DR; I won’t blame you, this turned into a bit of a novel), while you can make a diesel engine make power at high speeds, you’ll be doing so very inefficiently, with lots of soot, because many of the processes that need to occur in a CI diesel engine are more time-dependent than engine-speed-dependent, while the main driver for combustion speed in SI gas engines is engine-speed-dependent.